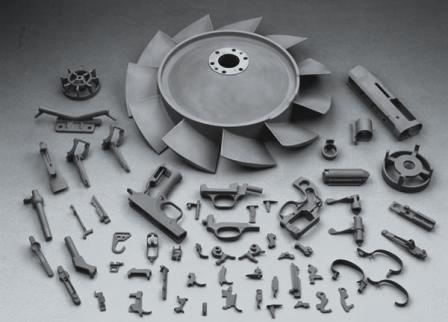

Precision Investment Casting

Investment Casting (Lost Wax Casting)

Investment casting, also called lost-wax casting, is one of the oldest known metal forming techniques. Investment castings allow the production of components with accuracy, repeatability, versatility and integrity.

While investment castings are generally more expensive than forged parts or those produced by other casting methods, they make up for the higher cost through the reduction of machining achieved through the near net-shape and tight tolerances that can be held as cast. Many parts that require milling, turning, drilling and grinding to finish can be investment cast with only .020-.030 finish stock.

The investment casting process maintains typical dimensional accuracy of +/-.005" per inch, with a surface finish of 125 RMS or better.

Engineering

We offer a wide range of engineering capabilities that enable us to produce the most complex parts, complete to print. In addition, our ability to design and produce all of our own tooling, fixtures, and assembly equipment in-house, allows us flexibility in delivering quality products, on time

Quality

At SMI every project, part and process is managed through our end-to-end quality assurance process to ensure that the best quality product is produced. Our proven quality system improves reliability and increases production output with fewer defects and outstanding client satisfaction.

Our primary facility has been very successful in utilizing the Precision Investment casting process to develop and manufacture net shape components in a wide range of alloys in conformance with ISO 9001:2008 & AS 9100 :2003 certifications.

Value-Added Services

SMI is a Full Service Caster provides comprehensive Value Added Services including engineering, tooling, machining, fabrication, finishing, & assembly in addition to our extensive precision investment casting turnkey capabilities.